Introduction to Sportswear Manufacturing Certifications

Sportswear manufacturing certifications ensure that products meet high standards for quality, safety, and sustainability. These certifications help manufacturers comply with global regulations and build consumer trust by showing a commitment to quality and ethical practices. Below are the top certifications that matter in sportswear manufacturing.

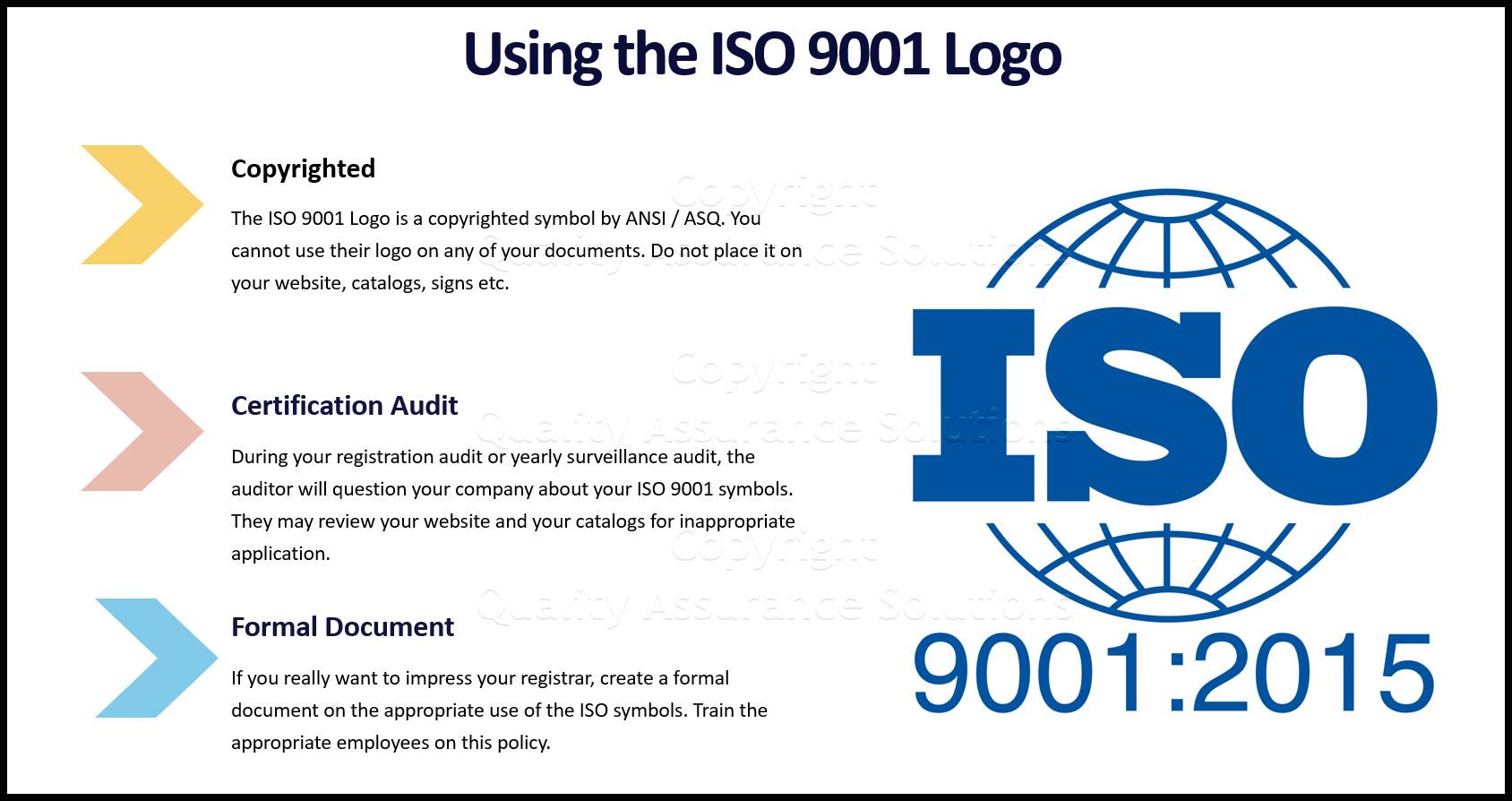

ISO Certifications

ISO certifications are essential in the sportswear industry. The ISO 9001:2015 certification ensures consistent quality management throughout production. This certification focuses on maintaining customer satisfaction by improving processes. Additionally, ISO/TC 83 standards guarantee compliance with safety and quality requirements specific to sportswear, including fabric performance and durability tests.

- ISO 16321 and ISO 18527 focus on areas such as eyewear and face protection for sports like squash and racquet sports. These certifications ensure safety standards are met and testing methods are consistent.

Environmental and Ethical Certifications

Several certifications focus on sustainability and ethical manufacturing. The Global Organic Textile Standard (GOTS) ensures that textiles come from organic materials and the manufacturing process is environmentally friendly. Another important certification is Social Accountability International (SA8000), which confirms that manufacturers follow fair labor practices and respect human rights.

- The Bluesign certification is one of the strictest in terms of safety and sustainability. It ensures harmful chemicals are excluded from production through thorough audits, making it highly relevant for manufacturers focused on reducing environmental impact.

Testing and Quality Assurance

Besides certifications, sportswear manufacturers undergo extensive testing to ensure safety and functionality. Testing includes checks for durability, colorfastness, and fabric performance. Third-party testing organizations like QIMA and HQTS play an important role in confirming that products meet safety, performance, and regulatory standards, such as REACH and ASTM.

- Durability tests ensure that sportswear withstands wear and tear in different conditions. Flammability tests, as well as checks for evaporative resistance, breathability, and stretch recovery, are also crucial for ensuring the final product is safe and functional.

Inspection at Various Stages

To maintain the highest quality, inspections are conducted at different stages of production, including pre-production, during manufacturing, and before shipment. These inspections help identify issues early, allowing for quick corrections. Inspections may include piece-by-piece checks, factory audits, and certifications from regulatory bodies to verify that products meet both national and international standards.

By following these certifications and testing procedures, sportswear manufacturers guarantee their products’ safety, quality, and ethical integrity, ensuring they meet the expectations of today’s consumers.

Quality and Safety Certifications

Quality and safety certifications are crucial for ensuring the reliability and safety of sportswear. These certifications not only guarantee consistent quality but also build consumer trust. Below are some key certifications that are essential for manufacturing high-quality sportswear.

ISO 16321 and ISO 18527

These standards outline the safety and quality requirements for athletic clothing, particularly in eyewear and face protection for sports like squash and racquet sports. They ensure that safety measures and standardized tests are integrated into manufacturing to offer better protection for users.

ASTM D6207 and ISO 6530

The ASTM D6207 standard, combined with ISO 6530, ensures that sportswear is durable enough for physical activities and outdoor conditions. These standards focus on material durability and make sure the sportswear stays safe and functional during intense physical activity.

STANDARD 100 by OEKO-TEX

This certification ensures that textiles are free from harmful substances. The STANDARD 100 label guarantees that sportswear, from yarn to finished product, is tested for over 1,000 harmful chemicals. It complies with global regulations such as REACH and CPSIA, ensuring that the clothing is safe for human health.

Consumer Product Safety Improvement Act (CPSIA)

For sportswear sold in North America, CPSIA certification ensures that products meet safety requirements. This certification is especially important for children’s apparel, ensuring that products are free from hazardous substances and safe for use.

International Standards in Asia

Countries like Japan and South Korea have their own safety standards, such as Japan’s Industrial Standards (JIS) and South Korea’s Textile Industry Act. These standards focus on the safety and quality of textiles used in sportswear, ensuring they meet the specific needs of these regional markets.

QIMA Certification

QIMA certification helps brands test their products for ISO compliance by evaluating material strength, dye safety, and overall quality. This certification ensures that the sportswear meets all necessary safety and durability criteria, reinforcing the brand’s commitment to consumer health and safety.

By following these certifications, sportswear manufacturers can increase brand credibility, boost consumer trust by 25%, and reduce risks by 40%. These certifications are essential for ensuring the safety and quality of sportswear, benefiting both manufacturers and their customers.

Sustainability and Eco-Friendly Certifications

Sustainability and eco-friendly certifications are important in the sportswear industry. They ensure that products are made using environmentally responsible practices. These certifications cover areas like organic materials, recycling, ethical manufacturing, and labor conditions. Below are some of the most recognized sustainability certifications:

Global Organic Textile Standard (GOTS)

- Criteria: Requires at least 70% organic fibers and strict rules on chemicals, water use, and social responsibility.

- Process: Involves on-site inspections throughout the manufacturing process to ensure compliance.

Global Recycle Standard (GRS)

- Focus: Ensures that products contain recycled materials and promotes textile recycling.

- Examples: Reebok uses this certification for their eco-friendly sportswear lines.

Better Cotton Initiative (BCI)

- Focus: Supports cotton farmers by teaching eco-friendly farming practices to reduce carbon emissions and water use.

- Examples: Reebok uses this certification to improve the sustainability of their cotton sourcing.

OEKO-TEX® Standard 100

- Focus: Certifies textiles that are free from harmful substances and produced responsibly.

- Examples: Brands like Girlfriend Collective, TALA, and P.E Nation carry this certification to ensure product safety.

B Corp Certification

- Focus: Recognizes businesses that address environmental and social issues through their operations.

- Examples: Patagonia and Girlfriend Collective are certified B Corps, showing their commitment to sustainability and ethical practices.

Fair Trade Certification

- Focus: Ensures that products are made under fair labor conditions and with ethical business practices.

- Examples: Patagonia and Girlfriend Collective are among the certified brands promoting fair trade practices in their manufacturing processes.

Fair Labor Association (FLA) Accreditation

- Focus: Verifies labor rights and corporate ethics across supply chains, ensuring fair and safe working conditions.

- Importance: This certification is important for brands committed to ethical manufacturing and responsible labor practices.

Cradle to Cradle (C2C)

- Focus: Supports a circular economy by ensuring products are designed for reuse, recycling, and sustainability throughout their lifecycle.

- Examples: The Cradle to Cradle certification encourages brands to adopt sustainable practices from product design to disposal.

Rainforest Alliance Certification

- Focus: Protects agricultural crops like cotton and wool, ensuring they meet organic and sustainable standards.

- Importance: This certification ensures that the materials used in sportswear production are grown and sourced responsibly.

Responsible Wool Standard (RWS)

- Focus: Ensures that wool is sourced from farms that follow high animal welfare standards.

- Examples: Brands using RWS-certified wool show a commitment to ethical and sustainable sourcing practices.

These certifications help brands and consumers make informed decisions about the sustainability and ethics of sportswear. By supporting eco-friendly practices, these certifications play a key role in reducing the environmental impact of the sportswear industry.

Social Responsibility and Ethical Practices Certifications

Social responsibility and ethical practices certifications are crucial for ensuring that sportswear manufacturers uphold high standards in protecting workers’ rights, promoting fair labor practices, and supporting sustainable environmental practices. These certifications demonstrate the commitment of brands to social and environmental causes, ensuring they follow ethical manufacturing processes. Below are some key certifications that matter:

Fair Labor Practices and Worker Welfare

- Ensures fair wages and safe working conditions: Certifications like Fair Trade and SA8000 guarantee that workers are paid fairly and work in safe environments, preventing exploitation in the supply chain.

- Focuses on labor rights and corporate ethics: These certifications maintain standards for fair wages, safe working conditions, and prohibit forced and child labor. They lay the foundation for ethical trade practices.

- Eradicates child labor: By following these certifications, companies ensure no child labor is used in the production process, contributing to the welfare of communities.

- Monitors and improves labor conditions: Certifications like Ethical Trading Initiative (ETI) and Global Organic Textile Standard (GOTS) require brands to protect workers’ rights, offering safeguards such as collective bargaining and safe working conditions.

Environmental and Social Impact

- Promotes ethical trade practices: Certifications like Fair Trade ensure that companies positively contribute to the economic and social well-being of the communities involved in production.

- Recognizes companies with positive social and environmental impact: Brands with certifications like GOTS and Oeko-Tex Standard 100 are recognized for their efforts to reduce environmental harm and promote social equity within their supply chains.

- Requires transparent and effective management: These certifications enforce transparency in sourcing, manufacturing processes, and community welfare contributions, ensuring that brands maintain responsible practices across all stages of production.

By obtaining these certifications, sportswear manufacturers not only meet industry standards but also show their commitment to creating a positive impact on both the environment and the communities that support their business.

Compliance and Testing Certifications

Compliance and testing certifications are essential for ensuring the safety, quality, and performance of sportswear products. Manufacturers who want to meet industry standards and consumer expectations must obtain relevant certifications. Here are some key certifications and tests in the sportswear industry:

ISO 16321 and ISO 18527

These certifications are important for sportswear, especially eyewear and face protection used in sports like squash and racquet sports. Brands must undergo testing to meet these standards, ensuring product safety and quality. Meeting these standards increases customer trust and guarantees that the products are suitable for demanding environments.

ASTM Standards

Several ASTM standards cover different aspects of sportswear fabric performance. These include: – ASTM D3780-14, ASTM D3782-14: Cover general sportswear fabrics and performance materials. – ASTM D4155-14, ASTM D4156-14: Apply to stretchable and weather-resistant fabrics.

Compliance with these standards is verified through certifications like the General Certificate of Conformity (GCC) and Children’s Product Certificate (CPC). These certifications ensure that products meet the required safety and performance benchmarks for consumer products.

REACH Compliance

The REACH regulation (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is critical for sportswear manufacturers. It requires extensive testing to ensure products are free from hazardous chemicals, protecting both the environment and consumer health. Compliance with REACH is mandatory in many markets, ensuring sportswear products are safe for end users.

Government Certifications

Government certifications help ensure that sportswear products meet local and international regulatory requirements. For example, the GS Mark Certification indicates that the product meets safety and performance standards. Obtaining such certifications reassures consumers that the products have passed rigorous testing.

Third-Party Testing Services

Third-party companies like QIMA and Intertek offer valuable testing and certification services for sportswear manufacturers. They test fabric performance, colorfastness, and durability, ensuring that products meet international standards such as ISO. These companies conduct tests such as the Evaporative Resistance Test and Stretch and Recovery Tests, ensuring each garment meets performance standards before reaching the market.

Performance and Lifecycle Testing

Performance and lifecycle testing are essential for assessing how sportswear performs in real-world conditions. Intertek and other testing bodies provide comprehensive tests on durability, breathability, and overall product lifecycle. These tests ensure that sportswear performs well during its intended use, whether it’s a pair of running shoes or a high-performance sports jacket.

By obtaining these certifications and passing rigorous tests, sportswear manufacturers not only comply with legal standards but also gain consumer trust. According to recent data, following ISO standards can increase customer trust by 25% and reduce risks by 40%.

Quality Control and Inspection Services

Ensuring high-quality standards in sportswear manufacturing is crucial for brand reputation and consumer satisfaction. Quality control and inspection services play a key role in this process by ensuring products meet safety, performance, and durability standards before they reach the market.

Key Types of Inspections

- Pre-production Inspections: Before production starts, it’s important to check that all raw materials, such as fabrics and components, meet the required specifications. These inspections help spot potential issues early.

- During-production Inspections: These inspections are done throughout production to monitor progress and identify defects in real time. This reduces errors and ensures high-quality final products.

- Pre-shipment Inspections: The final quality check happens before shipment. This ensures products meet all safety and quality standards set by the brand and global regulations.

Laboratory Testing for Sportswear Quality

Laboratory testing is crucial to make sure sportswear meets industry standards. Tests such as evaporative resistance, breathability, stretch and recovery, tear strength, and colorfastness are essential. Compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) ensures that materials used in sportswear are safe and free from harmful substances.

Key Certifications for Quality Control

- ISO 17020:2012: This certification ensures that inspection processes meet international standards for consistent quality control.

- ISO 17025:2005: This certification applies to testing laboratories, ensuring their procedures are accurate, reliable, and globally recognized.

- ISO 16321 and ISO 18527: These certifications focus on fabric performance, colorfastness, and durability, ensuring the safety and quality of sportswear.

- Oeko-Tex Certification: Oeko-Tex ensures that products are free from harmful chemicals, which is vital for sportswear meant for prolonged use.

- WRAP Certification: The Worldwide Responsible Accredited Production (WRAP) certification, including Platinum and Gold levels, indicates compliance with ethical labor practices and social and environmental standards.

Audits and Ongoing Compliance

Many companies, like Dynamic Sportswear, undergo annual audits by organizations such as SGS, INTERTEK, CSCC, and BV to stay compliant with quality and safety standards. These audits evaluate the manufacturer’s ability to meet both production and ethical requirements.

Consultancy and Continuous Improvement

Some quality control providers offer consultancy to help manufacturers improve their quality assurance processes, ensuring they stay up-to-date with industry best practices and international certifications. This ensures ongoing improvements in sportswear quality.

Benefits of Certifications

Certifications provide several benefits that improve the quality, credibility, and sustainability of sportswear products, ensuring they meet industry standards and consumer expectations.

Quality Assurance

Certifications help manufacturers maintain consistent product quality and follow strict safety standards. For example, the Informed Manufacturer certification requires regular testing for banned substances by ISO 17025 accredited labs, ensuring garments are free from harmful contamination at parts-per-billion levels[1]. This ensures that sportswear products are safe, durable, and of high quality.

Market Access and Credibility

Certifications such as Global Organic Textile Standard (GOTS) and Oeko-Tex help manufacturers access international markets, as many regions require certified products to meet health and safety regulations. These certifications build trust with consumers, enhancing a manufacturer’s reputation and making products more attractive in competitive markets[3][5].

Ethical Responsibility

Certifications highlight manufacturers’ commitment to ethical production. For example, the Better Cotton Initiative (BCI) trains cotton farmers in sustainable and fair practices, supporting both environmental and social well-being in the manufacturing process[5]. These certifications show that a company is dedicated to reducing its environmental impact and ensuring fair labor practices.

Consumer Confidence

Consumers are more selective today, looking for products that match their values. Certifications like Cradle to Cradle and GoodWeave prove that sportswear is produced with a focus on sustainability and responsible manufacturing practices. These certifications help build trust with consumers, ensuring the products they buy are safe, high-quality, and ethically made[3][5].

Regulatory Compliance

Certifications help manufacturers comply with industry regulations, reducing the risk of product recalls or penalties. For example, the Informed Manufacturer certification ensures manufacturers have strong quality control systems to prevent contamination and regulatory violations[1].

Environmental Benefits

Sustainably certified sportswear, like products certified by GOTS, ensures manufacturers meet high environmental standards. GOTS-certified products must contain at least 70% organic fibers and meet strict criteria for chemicals, water, and social practices, making it easier for consumers and brands to identify eco-friendly options[5].

Reduced Risk

Certifications reduce the risk of manufacturing non-compliant or unsafe products. Regular testing and quality control under certifications ensure that manufacturers maintain high standards, preventing potential regulatory fines or product recalls. This safeguards both consumers and brands[1].

Conclusion

Certifications play a crucial role in shaping the sportswear manufacturing industry by ensuring products meet high standards for quality, environmental impact, and labor practices. They help build consumer trust and offer manufacturers a competitive edge in global markets.

Key Takeaways from Top Certifications

-

Building Credibility and Market Access

Certifications like ISO 9001:2015 and WRAP show that manufacturers are reliable and follow necessary regulations. These certifications make it easier to enter markets with strict quality and ethical standards. -

Encouraging Sustainability and Ethical Practices

Certifications such as GOTS, GRS, and the Better Cotton Initiative (BCI) promote eco-friendly production, recycling, and responsible sourcing of materials. They align with the growing demand for sustainable sportswear. -

Meeting Consumer Expectations

As consumers become more aware of product safety and ethics, certifications like Oeko-Tex and SA8000 appeal to those who prioritize health, safety, and ethical values, ensuring products meet their needs. -

Supporting Industry Progress

Standardized certification frameworks make compliance easier and encourage overall progress toward a more sustainable and responsible sportswear industry.

By following these recognized certifications, manufacturers align with global standards and contribute to a more sustainable and ethically responsible future for sportswear production.