Ever since Lululemon launched its line, activewear has been popping up everywhere! If you want also to launch your own activewear brand from scratch, what problems might you face? You may wonder how much it will cost to start an activewear line. But the essential is to know how to make high-quality activewear clothing if you are totally new to the industry. Having and technical CAD design and Tech pack is key to successfully producing great samples and eventually quality products. In this post, we will introduce you to how to make a professional tech pack by yourself.

What Is A Tech Pack?

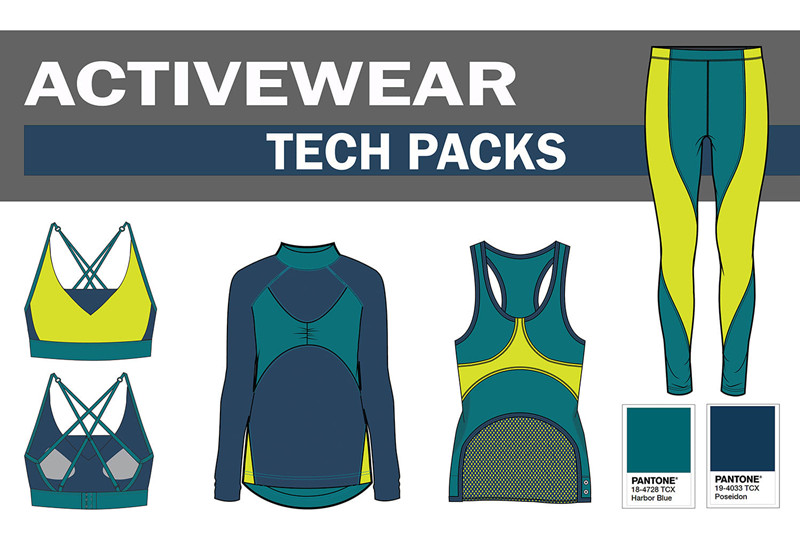

A tech pack is an informative sheet that designers create to communicate with a manufacturer all the necessary components needed to construct a product. Typically designers will include measurements, materials, colors, trim, hardware, grading, labels, tags, etc. Any crucial aspect of your design needs to be described in your tech pack. The more detailed a tech pack is, the less room there is for error.

Why Do I Need a Tech Pack?

A tech pack is one of the most crucial fashion business tools when you’re in the process of taking your ideas through to the production stage. It is important to have a detailed tech pack on hand when you are engaging in a conversation with your activewear manufacturer, and don’t be afraid to put down more detail than might seem necessary. After all, you don’t want to be financially responsible for any errors.

Differences Between Tech Packs and Spec Sheets

A specification sheet is a single document that describes most of the important details regarding your project. It displays a flat drawing of your design accompanied by a technical drawing for the manufacturer.

If you’ve been in the design industry for a while, it’s likely that you’ve heard the term “specification sheet” thrown around from time to time. While your spec sheet is another important tool in the process of making your design vision come to life, there are some important differences between tech packs and spec sheets that you should understand before moving forward.

How To Make a Professional Tech Pack on Your Own

- Sketches and Descriptions

Your tech pack should start with a black and white flat sketch that shows the front and back views of the garment. Make it as simple as possible, and do not use any color. You can also create digitized sketches with software such as Adobe Illustrator to create your images.

You can also create a style board of your brand. Here, add the images and patterns that inspired you to create the original ideas. These can include textures, prints, cuts, and styles that represent your vision. You also might want to add some comments to ensure it is clear that your images are translatable to the manufacturer.

- Materials aka BOM

After your design sketches and descriptions are in place, next in the order of your tech pack is materials. Bill of Material(BOM) represents all the hardware that you will need to make a complete garment, inside and out.

These materials are mainly fabrics (for the shell, lining, rib, pocket bag, or interlining), fasteners, threads, and of course label and care tags. You can also include your packaging material details if that too you are sourcing from your factory.

In a tech pack, it is important to clearly specify your materials requirement and placement. You might find it messy to jam all the info within a page, but you can always use lines and callouts on the images to keep them neat and organized.

- Size & Measurements

Once material information is clearly stated, up next is the most technical part of your tech pack – the measurements. If not properly specified, this can be a detrimental part of your design’s fit outcome.

First, it is important to determine your master size, or the sample size, e.g. Medium. And then you decide the complete size range you would like to offer in that style (e.g. XS, S, M, L, XL, etc.). Also remember, the more intricate your design, the more point of measurements (POM) you would have to mention in your tech pack. So once you have your size ranges together, the final step is grading. Grading is the measurement difference between every size of your style. And you calculate it from your master size. E.g. If your Medium-sized sample has a chest width say 15 inches, then the difference (in inches) you would want in your large size (say +1 or +2) is the grading that would have to provide for each POM and all size ranges.

- Color Choices

Identifying the specific colors that should be used is vital to get the look and style of the garment correct the first time. You should include the color name, number (Pantone color or original number), and color swatch. You can also add print colorways if your design does not include solid colors.

- Fabric Placement and Garment Construction

This section highlights the desired assembly of the clothing, and it should include construction diagrams. Sketches of your clothing should be marked about what type of material you want to be placed in certain areas including everything down to the small details such as label placement. For example, use stripes to indicate the use of one type of fabric and dots for another type. Label what each pattern corresponds to in a comprehensive key under the illustration.

Use as many arrows or notes as needed to get the message across, but when writing comments, always decrypt any abbreviations or acronyms you might have used. When it comes to garment assembly, it is vital to have clear codes for each type of print or fabric to avoid misinterpretation.

Is there a simpler way?

Usually, designers use programs like Excel and Illustrator to create tech packs. These are great tools for making tech packs but not necessarily the most efficient ones when it comes to regularly updating them and for team collaborations. So the best way is still to find a professional activewear manufacturer!

At Berunwear Sportswear company we manage the whole process from initial concept to discuss with our clients through the design, tech packs, BOM, sampling, and production to guarantee the vision is never diluted and the final product hits the agreed target price and is produced to the quality and performance required.

What’s more, you can just send us an image of activewear that you desire or a simple and original design of the garment, we can transfer it into tech packs then put them in production, that is:

Give us your idea, we bring your sportswear design to life.

No need to know much about Sportswear Production, we will handle all of the clothing manufacturing processes.

- Have a 10 persons’ sportswear designing expert team.

- Analyze the needs of the local market and manufacture the most proper sportswear.

- Suggest the right material, fabric, color, size, pattern, cutting, stitching, printing method.

Our sports garment supply service is a Comprehensive Customized Sportswear Solution.